C'est mon cinquième caisson grave, je peux dire que pour le prix, je n'ai pas été déçu. Puissant, clair avec des graves propres, je n'ai pas regretté le fait qu'il n'y ait pas de correction électronique. Le rapport qualité prix est passé de très bon à bon depuis la hausse du prix.

New Customer?

Create your accountNo products

Prices are tax included

By buying this product you get 199 loyalty points

Viewed products

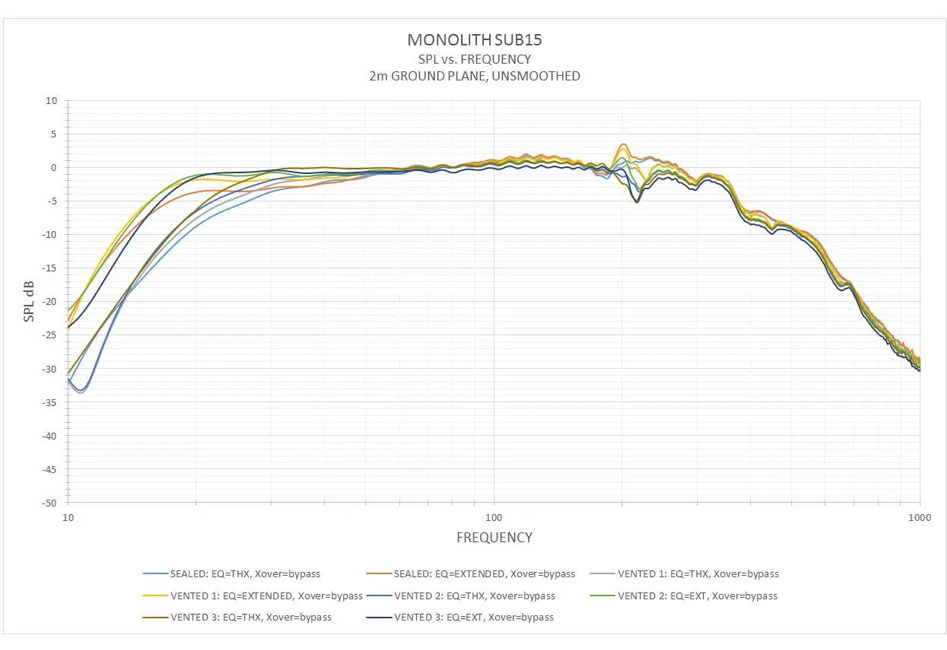

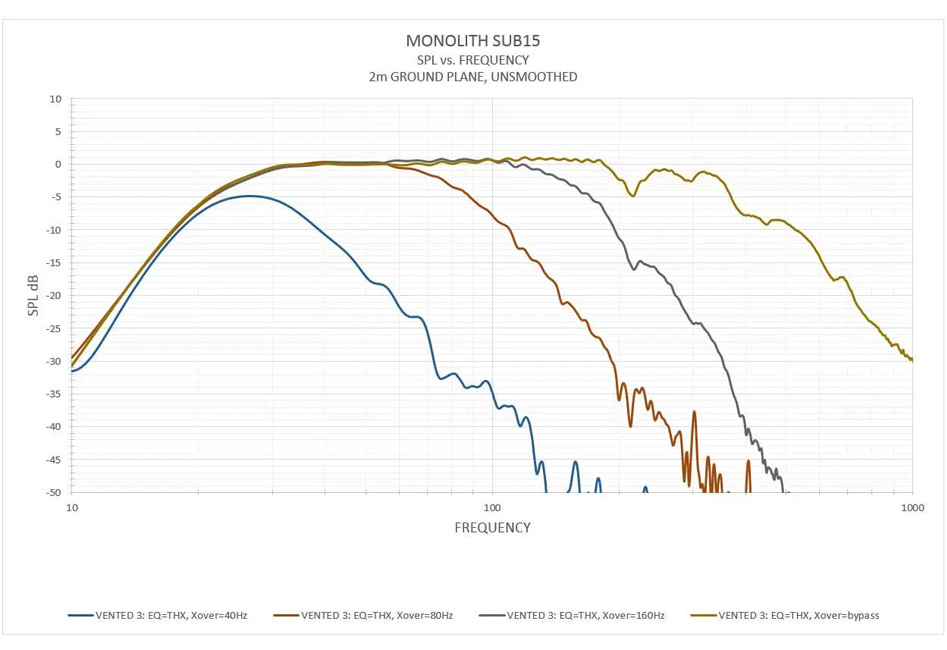

The THX® certified Monolith M-15 V2 subwoofer delivers deep bass with low distortion. Dropping below 16Hz, the Monolith M-15 V2 unleashes significant volume with the ability to convey and articulate the subtle nuances of your music or movies.

THX Ultra Certified

THX engineers have performed hundreds of different tests to ensure the best possible audio performance. These tests ensure that the speaker can reach high volumes without creating audible distortion or artifacts. THX Certified Ultra products are intended for large rooms, up to 85m³ in volume.

Woofer 15"

The 15" (38.1cm) driver used was developed with a design focused on achieving high efficiency, high precision, good dynamics and linearity, while minimizing distortion. It is housed in an HDF cabinet with massive internal bracing. It is equipped with three vents, which can be filled with foam plugs if necessary for a completely sealed operation.

1000W Amplifier

The 1000W integrated amplifier is built around a Texas Instruments 48bit architecture (with 28bit filter coefficients) and DSP. Each amplifier's transfer function, output power limiting and thermal protection are monitored to the millisecond. The high-performance Class D amplifier modules are based on a proven topology that has been continuously improved over the last 4 years. The amplifier has a large power reserve for accurate and deep bass, whether for a home theater or HiFi system.

The subwoofer in detail

Body and internal reinforcements : The use of HDF (High Density Fiberboard) instead of MDF results in a sonically inert cabinet. The internal bracing was intelligently placed to increase the overall strength of the cabinet and limit unwanted panel vibration, which could cause sound discoloration and distortion. The strength of the cabinet and the bracing combine to ensure massive bass, not resonance.

Vents and grids : The Monolith M-15 V2 uses three 88.5mm vents with internal and external flares. These multiple ports are used to ensure high sound pressure at low frequencies (fb=21Hz). The double flares are used to reduce asymmetric distortion. The vents can also be plugged with the supplied plugs. The "floating" grille is made from rigid MDF and is offset from the cabinet to maximize airflow from the woofer and vents.

15" Woofer

Every part of the driver has been developed to deliver high output, low distortion and accurate bass. Its unique diaphragm combines paper and fiberglass, taking advantage of the benefits of each material for high durability and impressive linear excursion capability. The result is a diaphragm capable of achieving optimal movement at any frequency it can be asked to produce.

1. Lower suspension : Finite Element Analysis (FEA) modeling and Klippel laser-based optimizations were used to design a diaphragm capable of impressive linear excursion. The lower and upper suspensions are designed in conjunction with the engine structure. The lower suspension is essential to maintain very low distortion levels at high excursions, which is essential to achieve high SPLs at low frequencies.

2. Spider and air vents : The spider is made from several layers of NOMEX® and installed by hand, ensuring low mass but high strength and durability. The advantages of the air vents are twofold: on the one hand, they allow air flow to effectively cool the voice coil, and on the other hand, they reduce asymmetrical compliance due to air compression under the diaphragm and the spider, which would manifest itself in unwanted distortions.

3. Membrane suspension : Again, FEA modeling and Klippel optimization are used to create the large membrane suspension. This suspension is made from a unique formulation of NBR (Nitrile Butadiene Rubber). This material was developed after months of prototyping to ensure the highest levels of excursion without sacrificing linearity or distortion.

4. Motor structure : The motor is made of CNC machined low carbon steel in an assembly to concentrate the magnetic flux. Rings are used to cancel eddy currents to further stabilize the magnetic flux and greatly reduce distortion. Precision winding, made of aluminum (which has lower thermal compression than copper) allows the coil to remain cool. The design of the motor and suspension is extremely important to ensure perfect control of the speaker's movement over a very wide range of input signals, for a high output level and minimal distortion.

High amplification power

The amplifier section of this subwoofer delivers an impressive 1000W RMS (2000W Max.). The Class D amplifier is built around a Texas Instruments 48bit DSP engine, allowing virtually unlimited design flexibility with the assurance of no signal degradation. The technology of this Class D amplifier ensures maximum power reserve, excellent transient response, high output and very low distortion.

Technical characteristics

| Specifications | |

|---|---|

| Product type | Subwoofer |

| Woofer diameter | 15" (38.1cm) |

| Cone material | Paper / Fiberglass |

| Voice coil diameter | Ø60mm |

| Surround | FEA optimized NBR |

| Magnet | x2 Céramic Y35 |

| Max linear excursion (Xmax) | 25mm |

| Xmech | 90mm (peak-to-peak) |

| Amplifier power | 1000W RMS |

| Frequency response | Extended EQ : 16Hz - 200Hz THX EQ : 20Hz - 200Hz |

| THD | < 1% 20Hz-100Hz (90dB @ 1m) |

| Variable level control | +15/-20dB |

| Crossover | Inline / Bypass variable 40Hz-160Hz |

| Inputs | 2x RCA 1x XLR |

| Output | 1x XLR |

| Auto ON (signal) | Switchable: Auto / Always On |

| General | |

|---|---|

| Finishes | Black Ash |

| Dimensions | 730x680x450mm |

| Net weight | 60kg |

| Color | Black |

| Impedance (Ω) | NC |

| Efficiency / Sensitivity (dB) | N/A |

| Lowest frequency (Hz) | 16 |

| Highest frequency (Hz) | 200 |

| Power (W) | 1000.0 |

| Number of loudspeakers | 1 |

| Speaker type | Active |

Average votes 5.0 / 5 1 reviews | Why write products reviews ? You can share your feelings about products and help other people by sharing your experience |

Philippe S.

C'est mon cinquième caisson grave, je peux dire que pour le prix, je n'ai pas été déçu. Puissant, clair avec des graves propres, je n'ai pas regretté le fait qu'il n'y ait pas de correction électronique. Le rapport qualité prix est passé de très bon à bon depuis la hausse du prix.