New Customer?

Create your accountNo products

Prices are tax included

Electrical conductivity of materials and IACS index

In this article, we'll look at the electrical conductivity of different materials and the IACS (International Annealed Copper Standard). Whether it's copper, gold, silver or other materials such as rhodium, nickel or the various copper alloys available, none has the same conductivity. It is therefore sometimes difficult to judge the quality of a connector or cable if the conductivity of the material is unknown.

A bit of history...

First of all, we should know that the term electricity was formed from the Greek ἤλεκτρον / ḗlektron, which in ancient Greek times referred to yellow amber, a kind of resin with electrostatic properties. But it was much later that electricity as we define it today was discovered and theorized. Actually, it was in 1600 that a man named William Gilbert, studying compasses, associated the attraction of magnets and amber, and came up with the term. From then on, numerous researchers, scientists and mathematicians contributed to advances in the field: Isaac Newton, Benjamin Franklin, André-Marie Ampère, Georg Ohm, Stephen Grey, Michael Faraday, Graham Bell, Thomas Edison and Nikola Tesla to name only a few.

Then, in 1880, electricity began to be mass-produced, gradually replacing gas for household lighting. This period saw the first power plants (hydroelectric at the time) and the first major power networks, at least in France and the United States. This raised the question of how to transport energy and power. It was this very question that led to the famous war between DC and AC, the winner of which you know today. It's also worth mentioning that the first cables were made of iron, which was very difficult to produce. But tests soon revealed the conductivity of copper. Copper conductors quickly became the standard.

It wasn't until 1913 that the International Electrotechnical Commission established the IACS (International Annealed Copper Standard) as the reference point for copper resistivity, equivalent to 100% conductivity. This standard is still used today to determine the conductivity of various materials.

But what exactly is an electrical conductor?

An electrical conductor is a material that allows an electric current to flow through it. Generally speaking, these are metals such as silver, copper and gold, to name only a few. Some conductors today are alloys, i.e. combinations of different materials, some of which may not be metals, such as graphite. Conductors generally have several characteristics:

- High electrical conductivity: ability to conduct electric current.

- Low resistivity: current flows with low opposing forces.

- High melting point: withstands high temperatures without melting.

- Ductility: can be shaped and extended into threads without breaking.

- High density: high mass per unit volume.

On the other hand, some materials have opposite properties and conduct little or no electrical current, and are therefore considered insulating materials. Insulators are often made of plastic or rubber, for example.

How does current flow through materials?

To understand how current flows through materials, we need to go back to their basic constitution. Simply put, they're a collection of atoms, themselves made up of a nucleus and a number of electrons. The nucleus of an atom is positively charged, while the electrons are negatively charged and gravitate around the nucleus. The closer an electron is to the nucleus, the greater is its attractive force, while the further away it is from the nucleus, the weaker is its attractive force. This is when free electrons come into play. Some electrons are able to move from one atom to another. Without any electrical action, these electrons move in a disordered movement. But if, for example, you connect a metal wire to the ends of a battery, the electrons will move together from the (-) terminal to the (+) terminal of the same battery. Note, however, that the direction of the current is reversed in relation to the movement of the electrons. The electric current moves, in this case, from the (+) terminal to the (-) terminal of the battery.

Conductivity of materials according to the IACS standard

The most widely used conductive material today is still copper. Some other materials, such as gold and silver, are also often used as conductors or simply as plating, due to their additional advantages. Here are the main materials and their advantages:

- Silver: this is the most conductive metallic material, with an IACS of 106%, and even 107% for OCC silver. Quite expensive, it is most commonly used as plating on connectors or cable conductors. However, some top-of-the-range products feature contacts or conductors made entirely from silver.

- Copper: this is the material of choice for conducting electricity. The IACS standard is even based on its conductivity, with a rating of 100%. The OFC (Oxygen Free Copper) and OCC (Ohno Continuous Casting) versions have now been introduced for superior quality, with conductivities of 101% and 103% IACS respectively.

- Gold: although its conductivity drops to 76% IACS, gold is often used for plating, since it has corrosion and oxidation-resistant properties.

- Aluminium: despite being less conductive than copper, aluminium has a conductivity of 62% IACS, making it a very good conductor. Its stable market price and characteristics such as lightness and malleability make it widely used for applications such as large cables and overhead lines, for example. In audio applications, aluminum is often used for shielding. However, you'll find some so-called CCA cables on the market, made of copper-plated aluminum.

- Rhodium, Nickel, Platinum, Paladium, Beryllium, Tellurium: these are often used in plating or alloying with copper on connectors, making them resistant to corrosion and oxidation while keeping a silvery appearance.

- Brass (copper + zinc), Bronze (copper + tin): Brass and bronze are copper alloys. They are mainly used for their low cost and good conductivity, but they are not as efficient as pure copper. Their conductivity depends on the percentage of the different materials that make them up. Brass is the most widely used copper alloy because of its resistance to corrosion.

| Matériau | Résistance nOhm-m | Conductivité 109S/m | IACS |

|---|---|---|---|

| OCC Silver | - | - | 107% |

| Silver | 15.87 | 0.0630 | 106% |

| OCC Copper | - | - | 103% |

| OFC Copper | - | - | 100-101% |

| Copper | 16.78 | 0.0596 | 100% |

| Gold | 22.14 | 0.0452 | 76% |

| Pure Aluminum | 22.14 | 0.0452 | 62% |

| Rhodium | 43.3 | 0.0231 | 39% |

| Nickel | 69.3 | 0.0144 | 24% |

| Platinium | 105 | 0.0095 | 16% |

| Palladium | 105.4 | 0.0095 | 16% |

* The data collected comes from various web sources, and is not exhaustive.

| Alliage | IACS |

|---|---|

| C10100 (Electronic grade OFC copper) | 101% |

| C10200 (OFC copper) | 100 - 101% |

| C11000 (OFC ETP Copper) | 100 - 101% |

| C14500 (Tellurium Copper) | 93% |

| C17500 (Beryllium Copper) | 45% |

| C31400 (Commercial leaded bronze) | 42% |

| C17530 (Beryllium Copper) | 38% |

| C37700 (Forging Brass) | 27% |

| C27450 (Yellow Brass) | 27% |

| C36000 (Free-Cutting Brass) | 26% |

| C17300 (Beryllium Copper) | 22% |

| C54400 (Phospor Bronze B2) | 19% |

| C53400 (Phospor Bronze B1) | 15% |

* The data collected comes from various web sources, and is not exhaustive.

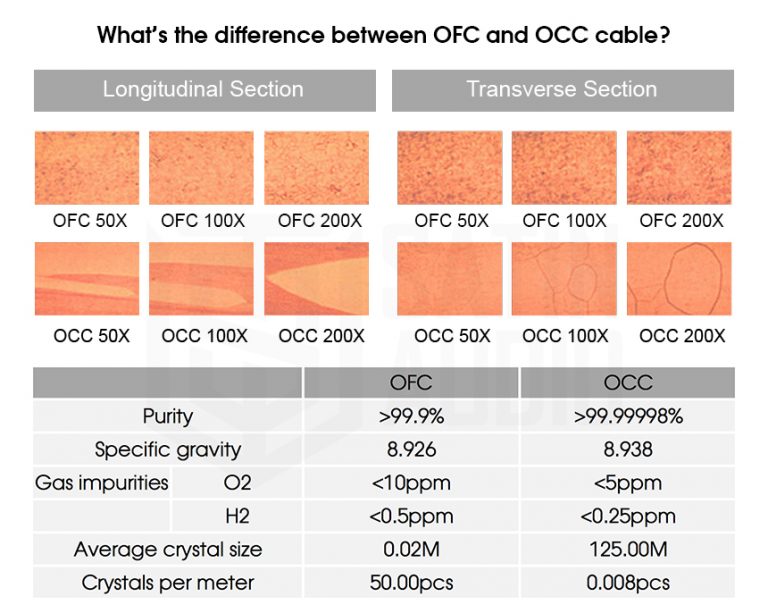

Going further: OCC copper VS OFC copper

We mentioned above the existence of these two types of conductor, and although one seems to be better classified in terms of conductivity according to the IACS standard, the debate over OFC copper and OCC copper remains vigorous within audiophile circles. But what is the real difference between OFC and OCC copper?

Both types of those conductors were first developed in Japan. The first to be created was OFC copper in 1975, a very pure oxygen-free copper. This copper is often characterized by the industrial designation 4N, meaning 99.99% purity, 5N 99.999% purity, and so on. OFC copper is composed of a multitude of small crystals. You will also often come across OFHC copper, which stands for oxygen-free copper with high thermal conductivity. Within OFC copper, there are 3 main types of composition: C10100, C10200, C11000.

As for OCC (Ohno Continuous Casting) copper, it only appeared 10 years later, in 1985. As its name suggests, it was developed by Professor Ohno of Chiba University. Professor Ohno's starting point was a simple observation: to improve the quality of a conductor and eliminate impurities, you need to reduce the number of crystals in it. This is equivalent to reducing the number of barriers that electrons have to jump over.

Some will say that OCC copper offers a much better quality and greatly improves sound quality in terms of clarity, dynamism and transparency, while others will prefer OFC copper for a warmer sound and a more reasonable price. We invite you to make up your own mind by testing different modulation or speaker cables.

A few examples of high-end cables and connectors with silver conductors/contacts

NEOTECH NEMOI-1220

Shielded UP-OCC Silver Interconnect Cable RCA-RCA Ø 10mm 0.5m (Pair)

349,00€ (280,83€HT)

AECO ARP-4055

RCA connectors Pure Silver Ø10mm (Set x4)

169,00€ (140,83€HT)

VIBORG VR106G

Male RCA Connectors Pure Silver PTFE Ø11mm (Set x4)

159,00€ (132,50€HT)

FURUTECH FX-Alpha-Ag

Pure Silver Cable 75 ohm Ø8mm

69.90€ (58.25€HT)

A few examples of cables and connectors with OCC/OFC copper conductors/contacts

NEOTECH SOCP-20

Wiring UP-OCC Copper Cable PVC 20AWG Ø2.6mm

3,80€ (3,17€HT)

NEOTECH NEX-OCC GD

Gold-Plated UP-OCC Copper 3 way Male / Female XLR Connectors Ø13mm (Set x4)

229,00€ (190,83€HT)

.jpg)

FURUTECH FP-108 (R)

Plug Connectors Rhodium Ø9.2mm (Set x4)

219,00€ (182,50€HT)

AUDIOPHONICS WIRE

Interconnect Cable Stereo RCA OFC Copper Gold Plated 75cm (Pair)

39,90€ (33,25€HT)

AUDIOPHONICS WIRE

Interconnect Cable Stereo XLR OFC Copper Gold Plated 75cm (Pair)

44,90€ (37.42€HT)

Rechercher dans le blog

Blog categories

Latest Comments

Audiophonics Team

on DIY Tutorial - PiCorePlayer - Installing...Pierre Bommel

on Lecteur réseau Opensource : SolutionsPierre Bommel

on DIY Tutorial - PiCorePlayer - Installing...Audiophonics Team

on Tutorial DIY - Power cable ELECAUDIO CS-331B