New Customer?

Create your accountNo products

Prices are tax included

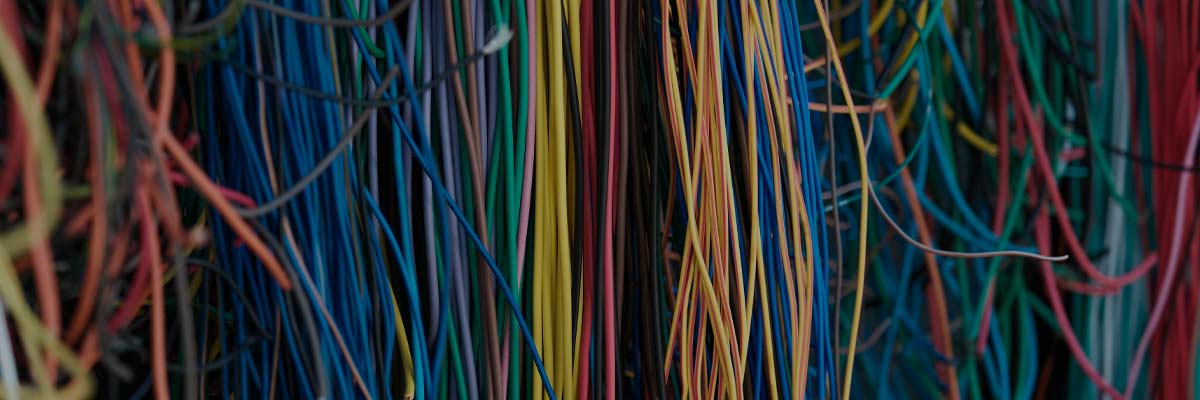

Understanding cable diameters and AWG cross-sections

How to choose your cable

The importance of conductor diameter and AWG cross-section

Have you ever wondered which cable cross-section to choose? Here you'll find all the information you need to answer that question. Indeed, the cross-section of a cable is one of the most important elements to take into into account, as it has a considerable impact on the transmission of an electrical signal, depending on the current and length of the cable required.

But what exactly is AWG?

AWG or American Wire Gauge is simply a unit of measurement used to define the diameter of a conductor. This system of measurement first appeared in the United States thanks to a man named J.R. Brown in 1857. It was the foundation for the standardization of cable production. J.R. Brown introduced 39 intermediate intervals to make it easier for users to find their way around. The AWG unit of measurement is closely linked to the way cables are produced, since it actually means the number of passes through the wire-drawing machine*, in other words 20 passes through the wire-drawing machine for an AWG20 conductor. But how do you tell the difference between the AWG cross-section and the diameter of a cable? In the logic of cable production, the larger the AWG, the smaller the cable diameter. In a decreasing progression of AWG values, a conductor doubles its diameter every 6 intervals. For example, an AWG 10 cable will have twice the diameter of an AWG 16 cable. Every 3 gauges, the cross-sectional value in mm² doubles. This order of progression can also be seen in the relationship between a signal's decibel level and its power: +3dB is equivalent to a 2-fold increase in power. This is a logarithmic progression.

*Wire-drawing machine: Technique of cold-drawing certain metals to transform them into wire by successive passes through the holes of different dies. This process is carried out using industrial or smaller-scale machines. This technique is also used in the jewelry and pasta industries, for example.

AWG gauge: how does a cable's cross-section affect its use?

A cable's cross-section not only influences its diameter, but also the conductor's resistance. That's why it's important to choose the right cable cross-section for your application. The higher the current you want to pass through your cable, the greater the cross-sectional area required. A second factor to consider is the length of the cable. The longer the cable, the greater the cross-sectional area required to limit signal loss. This is particularly true for speaker cables, for example.

AWG gauge: multi-stranded conductors

Some conductors are multi-stranded. In other words, they are themselves made up of several interwoven conductors. This is why AWG is not calculated on the basis of the finished cable, but on the basis of the internal conductors. A cable with a multi-strand conductor, for example, will have a cross-section of 200x 0.02mm², i.e. a cross-section of 4mm². The advantage of a multi-strand cable over a single-strand cable lies in its greater flexibility, but above all, it reduces the skin effect. That's why we often use Litz wires for audio applications!

Skin effect is an electromagnetic phenomenon that affects cables carrying alternate current. At high frequencies, the current will flow more on the surface of the conductor, resulting in an increase in conductor resistance and a decrease in current density. In other words, there's a loss of signal at high frequencies. To counteract this skin effect, we use a specialized multi-strand wire called Litz wire. Litz wire consists of several insulated strands woven together in a precise manner. This allows the overall magnetic field to be evenly distributed, and thus the current to be evenly distributed between each strand. Compared with a single-strand conductor, Litz wire considerably reduces the skin effect and avoids signal loss.

What are the risks of a cable with the wrong cross-section?

If a cable's cross-section is insufficient, it will heat up due to excessive resistance. This can lead to fire. Insufficient cable cross-section can also lead to voltage losses, thus affecting audio signal transmission. On the contrary, a cable with a larger cross-section than necessary will not necessarily affect the signal: as they say, who can do more can do less! Beware, however, that this may have an impact on the price, weight and handling of the cable.

But how do you navigate between the different units of measurement? Diameter, mm² cross-section, AWG gauge and resistance?

Here's a summary table to help you find your way around, so you can select the right cable or recognize a cable you already have. The values in this table are given for bare, single-core copper wire. Take into account that audio cables are often multi-stranded.

| GAUGE AWG | Cross-Section mm² | Diameter mm | Resistance(ohm/km) | Maximum current Ampere | Maximum frequency (for 100% skin depth) |

|---|---|---|---|---|---|

| 0000 (4/0) AWG | 107mm² | 11.684mm | 0.17Ω/km | 302A | 125Hz |

| 000 (3/0) AWG | 85.0mm² | 10.40384mm | 0.21Ω/km | 239A | 160Hz |

| 00 (2/0) AWG | 67.4mm² | 9.26592mm | 0.26Ω/km | 190A | 200Hz |

| 0 (1/0) AWG | 53.5mm² | 8.25246mm | 0.33Ω/km | 150A | 250Hz |

| 1AWG | 42.4mm² | 7.34822mm | 0.40Ω/km | 119A | 325Hz |

| 2AWG | 33.6mm² | 6.54304mm | 0.51Ω/km | 94A | 410Hz |

| 3AWG | 26.7mm² | 5.82676mm | 0.64Ω/km | 75A | 500Hz |

| 4AWG | 21.2mm² | 5.18922mm | 0.81Ω/km | 60A | 650Hz |

| 5AWG | 16.8mm² | 4.62026mm | 1.03Ω/km | 47A | 810Hz |

| 6AWG | 13.3mm² | 4.1148mm | 1.30Ω/km | 37A | 1100Hz |

| 7AWG | 10.5mm² | 3.66522mm | 1.63Ω/km | 30A | 1300Hz |

| 8AWG | 10.5mm² | 3.66522mm | 1.63Ω/km | 24A | 1650Hz |

| 9AWG | 6.63mm² | 2.90576mm | 2.60Ω/km | 19A | 2050Hz |

| 10AWG | 5.26mm² | 2.58826mm | 3.28Ω/km | 15A | 2600Hz |

| 11AWG | 4.17mm² | 2.30378mm | 4.13Ω/km | 12A | 3200Hz |

| 12AWG | 3.31mm² | 2.05232mm | 5.21Ω/km | 9.3A | 41.50Hz |

| 13AWG | 2.62mm² | 1.8288mm | 6.57Ω/km | 7.4A | 3300Hz |

| 14AWG | 2.08mm² | 1.62814mm | 8.29Ω/km | 5.9A | 6700Hz |

| 15AWG | 1.65mm² | 1.45034mm | 10.4Ω/km | 4.7A | 8250Hz |

| 16AWG | 1.31mm² | 1.29032mm | 13.20Ω/km | 3.7A | 11KHz |

| 17AWG | 1.04mm² | 1.15062mm | 16.60Ω/km | 2.9A | 13KHz |

| 18AWG | 0.823mm² | 1.02362mm | 20.90Ω/km | 2.3A | 17KHz |

| 19AWG | 0.653mm² | 0.91186mm | 26.40Ω/km | 1.8A | 21KHz |

| 20AWG | 0.518mm² | 0.8128mm | 33.30Ω/km | 1.5A | 27KHz |

| 21AWG | 0.410mm² | 0.7239mm | 41.99Ω/km | 1.2A | 33KHz |

| 22AWG | 0.326mm² | 0.64516mm | 52.95Ω/km | 0.92A | 42KHz |

| 23AWG | 0.258mm² | 0.57404mm | 66.80Ω/km | 0.729A | 53KHz |

| 24AWG | 0.205mm² | 0.51054mm | 84.20Ω/km | 0.577A | 68KHz |

| 25AWG | 0.162mm² | 0.45466mm | 106Ω/km | 0.457A | 85KHz |

| 26AWG | 0.129mm² | 0.40386mm | 134Ω/km | 0.361A | 107KHz |

| 27AWG | 0.102mm² | 0.36068mm | 169Ω/km | 0.288A | 130KHz |

| 28AWG | 0.0810mm² | 0.32004mm | 213Ω/km | 0.226A | 170KHz |

| 29AWG | 0.0642mm² | 0.28702mm | 268Ω/km | 0.182A | 210KHz |

| 30AWG | 0.0509mm² | 0.254mm | 339Ω/km | 0.142A | 270KHz |

| 31AWG | 0.0404mm² | 0.22606mm | 427Ω/km | 0.113A | 340KHz |

| 32AWG | 0.0320mm² | 0.2032mm | 538Ω/km | 0.091A | 430KHz |

| 33AWG | 0.0254mm² | 0.18034mm | 679Ω/km | 0.072A | 540KHz |

| 34AWG | 0.0201mm² | 0.16002mm | 856Ω/km | 0.056A | 690KHz |

| 35AWG | 0.0160mm² | 0.14224mm | 1079Ω/km | 0.044A | 870KHz |

| 36AWG | 0.0127mm² | 0.127mm | 1361Ω/km | 0.035A | 1100KHz |

| 37AWG | 0.0100mm² | 0.1143mm | 1716Ω/km | 0.0289A | 1350KHz |

| 38AWG | 0.00797mm² | 0.1016mm | 2164Ω/km | 0.0228A | 1750KHz |

| 39AWG | 0.0889mm² | 0.00632mm | 2729Ω/km | 0.0175A | 2250KHz |

| 40AWG | 0.00501mm² | 0.07874mm | 3441Ω/km | 0.0137A | 2900KHz |

| 41AWG | 0.0711mm² | 0.00397mm | 4340Ω/km | - | - |

| 42AWG | 0.00315mm² | 0.0633mm | 5470Ω/km | - | - |

| 43AWG | 0.0025mm² | 0.0564mm | 6900Ω/km | - | - |

| 44AWG | 0.00198mm² | 0.0502mm | 8700Ω/km | - | - |

| 45AWG | 0.00157mm² | 0.0447mm | 11000Ω/km | - | - |

| 46AWG | 0.00125mm² | 0.0398mm | 13800Ω/km | - | - |

Use examples of cables with different cross-sections

Domestic use

For domestic use, the voltage used (in Europe) is 230V. For this type of use, single-core cables are preferred. Here are some suitable cross-sections according to the type of power required:

- 1.5mm² → 10 A → 2 300 W (controlled lighting and sockets, domestic V.M.C....)

- 2.5mm² → 16 A → 3 680 W (16A sockets, washing machine, dishwasher, oven, roller shutters, etc.)

- 4mm² → 25 A → 5 750 W (electric water heater, oven, stoves, three-phase hobs)

- 6mm² → 32 A → 7 360 W (stoves, single-phase hobs, etc.)

- 10mm² → 40 A → 9 200 W

Audiophile use

To determine the cross-section of your cable, you first need to identify your various needs, starting with the type of cable: RCA modulation cable, XLR modulation cable, speaker cable, mains power cable or digital cable, etc. The diameter and cross-section of a cable don't really affect signal or data cables, and therefore modulation or digital cables, since the signal is not an amplified signal. That's why we'll be talking mainly about speaker cables and power cables carrying high currents. In fact, RCA or XLR modulation cables often have small cross-sections, as the signal power to be transported from one device to another is lower. For data, the signal is even weaker. That's why USB cables, for example, despite having multiple conductors, are so thin. Speaker cables, on the other hand, carry an amplified signal, which is why the maximum power level of your amplifier, as well as the impedance of your speakers and the materials of the cable, must be taken into account when choosing the latter.

Which cross-section for HP cables?

First and foremost, if you're looking to carry out a DIY HP cable project, the first parameter to consider is the length of your cables. You should also ensure that your cables are more or less equal in length for your left and right channels, otherwise there may be a risk of phase shift, meaning a time lag between the arrival of the signal on your different speakers that could be felt when listening. This is especially true for high-end systems. The acoustic configuration of your room and the positioning of your speakers will make much more difference to your listening experience. It's even better to have two cables of different lengths than to wind one of them, which would change the apparent impedance of the speaker to your amplifier.

The main factors to consider are the power of your amplifier and the impedance of your speakers. In simple terms, the higher the power of your amplifier and the higher the impedance of your speakers, the larger the diameter of the cable you'll need, and therefore the larger the cross-section. To give you an order of magnitude, you can refer to the table below. If you need a cable length of between 10 and 25m, we advise you to use the cross-section value for the higher power. Bear in mind, too, that who can do more can do less. It's perfectly possible to use a cable with a cross-section of 6mm2 for a power of 100W, even if this wouldn't be very useful. The minimum cross-section for HP cables without risking damage is 0.75mm².

| Puissance Max. Amp | Recommended cross-section | HP Resistance | Cable length |

|---|---|---|---|

| ≤ 100W | 0.75mm² (AWG17-18) | 4Ω-6Ω-8Ω | ≤10m |

| ≤ 150W | 1.5mm² (AWG15-16) | 4Ω-6Ω-8Ω | ≤10m |

| ≤ 250W | 2.5mm² (AWG12-13) | 4Ω-6Ω-8Ω | ≤10m |

| ≤ 400W | 3.31mm² (AWG11-12) | 4Ω-6Ω-8Ω | ≤10m |

| ≤ 500W | 4mm² (AWG9-10) | 4Ω-6Ω-8Ω | ≤10m |

| ≤ 1000W | 6mm² (AWG8-9) | 4Ω-6Ω-8Ω | ≤10m |

A further complexity lies in the fact that some loudspeakers can be used with bi-wiring or bi-amplification. In this case, smaller cross-sections are preferred for high frequencies, and larger cross-sections for low frequencies.

Wich cross-section for power cables?

The first thing to remember on this subject is that the power consumed by a device is inevitably greater than the power used or delivered. For instance it's the case with amplifiers. Most mains cables have a cross-section of 1.5mm² to 6mm². Technically, if you plug a 1.5mm² power cable into a 230V power outlet, you can power a device consuming up to 2300W, so most devices in fact. This is why the majority of power cables supplied with Hi-Fi equipment have a 1.5mm² conductor cross-section.

However, some audiophiles prefer cables with larger cross-sections, often with special shielding and plating to limit noise and potential interference from the mains current used to power their equipment.

Rechercher dans le blog

Blog categories

Latest Comments

Audiophonics Team

on DIY Tutorial - PiCorePlayer - Installing...Pierre Bommel

on Lecteur réseau Opensource : SolutionsPierre Bommel

on DIY Tutorial - PiCorePlayer - Installing...Audiophonics Team

on Tutorial DIY - Power cable ELECAUDIO CS-331B

![[GRADE A] MATRIX ELEMENT M Streamer DAC ES9028Pro WiFi AirPlay DLNA MQA 32bit 768khz DSD512](https://www.audiophonics.fr/65635-thumb_default/matrix-element-m-streamer-dac-es9028pro-wifi-airplay-dlna-mqa-32bit-768khz-dsd512.jpg)